Our Vehicle

Mechanical Architecture of Our Vehicle

During the design process, we focused on originality, manufacturability, and functionality. Unlike classic AUVs, our hull is a single, integrated structure that acts as both chassis and pressure-tight enclosure. Topology optimization enabled variable wall thicknesses (4–7 mm) in the PA12 shell, which is additively manufactured via selective laser sintering (SLS) to balance lightness, strength, and leak-tightness.

The overall vehicle dimensions are 600 × 600 × 440 mm, and its mass-to-volume ratio is tuned for about 1.4 % positive buoyancy, keeping the vehicle slightly upward-stable underwater.

The vehicle comprises five main sub-systems: the hull, torpedo launcher, grabber, marker dropper, and ballast system.

Shell Design

Unlike traditional AUV designs, the vehicle's hull serves both as the chassis and a watertight tube. Inspired by stingrays and sharks, the hull is 600 × 600 × 240 mm in size, produced from AlSi10Mg material using the SLM method, and is symmetrically designed. The center of gravity and the center of volume are at the same point. This minimizes the static balance issues caused by the buoyancy force. The wall thickness ranges from 4 to 7 mm. The top cover is in the shape of a half-cylinder and is fixed with a special flange containing reinforced glass.

Sealing is achieved with O-rings and underwater assembly adhesives. Cable transitions are made using IP68 certified SubConn connectors. Internal structures of the hull are made of PA12, which is resistant to 70 °C, making it easier to arrange the electronic components. The outer surface is protected with an environmentally friendly epoxy coating in blue-gray tones.

.png)

Modular System

The underwater vehicle we are developing is designed with a modular structure to adapt to the varying requirements of different competitions and tasks. Thanks to the connection systems integrated into the vehicle's bottom and top, marker droppers and torpedo equipment can be attached to the vehicle without causing any damage and in a way that is compatible with the vehicle's geometry. This structure aims to enhance the flexibility and functionality of our vehicle by providing solutions suitable for the different technical requirements of each competition.

For instance, in platforms like the RoboSub Competition, tasks such as marker dropping and torpedo launching will require the use of integrated connection systems. In contrast, since there are no marker dropping or torpedo launching tasks in the TEKNOFEST Unmanned Underwater Vehicle Competition, our vehicle will participate without the integrated connection systems.

When positioning the integrated connection systems on the vehicle, the locations of cameras, sensors, and other fixed components were also taken into account. This ensures that systems added later will perform their tasks without obstructing the view of the sensors and cameras. In summary, this modular approach will allow for easy addition of new task systems to the vehicle, while also significantly simplifying maintenance and development processes.

.png)

.png)

.png)

.png)

.png)

_edited.png)

Torpedo System

The torpedo system developed for the RoboSub competition operates with a spring-based launch mechanism. The system consists of two hydrodynamically designed projectiles, approximately 4 cm in diameter and 10 cm in length, and the mechanism that launches them.

Pneumatic and electromagnetic solutions were eliminated due to additional volume, sealing, and control challenges; instead, a space-efficient, reliable, and low-cost spring-based system was chosen.

The rack-and-pinion arrangement, rotated by a step motor, releases the spring-controlled mechanism and pushes the projectiles along the rail. The dual-chamber design allows for two consecutive shots. The projectiles are designed with fins on the rear to prevent spinning in the water, and they are fixed to the rail system. During firing, small springs holding the projectiles in place open sideways to allow the projectiles to be released.

Thanks to its compact design, the system is fixed to the vehicle through a special attachment integrated into the top cover. It fully meets the competition requirements due to its safety, efficiency, and ease of production.

Grabber System

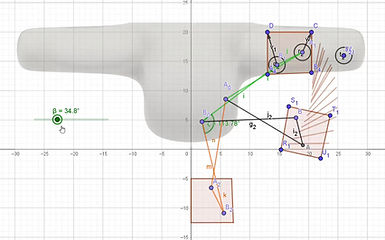

For object handling tasks, a symmetric gripper system is designed to be embedded into both wings of the vehicle. The grippers have a four-bar mechanism and, during the task, they open synchronously to the outside, lowering to the vehicle's underside to grasp the object.

The link mechanism connecting the gripper's head to the motor has been kinematically synthesized with the help of GeoGebra and is specifically designed for the vehicle's hull structure. A pin-based system with small springs is designed for the part of the gripper (the head) that will grasp the object. Each pin is covered with rubber material. This system provides a strong grip by adapting to the shape of the object being held. The gripper performs tasks successfully with its unique and functional design.

_edited.png)

Marker Dropper System

The Marker Dropper has a cylindrical body with a diameter of 160 mm and a height of 60 mm, and it carries two markers with a diameter of 38 mm each. The system includes a rotating disk and a servo motor. A marker is dropped with every 90-degree rotation.

The motor operates within a sealed bearing and O-ring supported chamber. This system saves space and ensures the markers are dropped in sequence.

.png)

Sinking and Floating System

One of the most critical systems in underwater vehicles is the ballast and buoyancy mechanism, which allows the vehicle to descend to the desired depth and rise to the surface when needed. This system is designed based on Archimedes' principle, with the buoyancy force controlling the vehicle's sinking and floating.

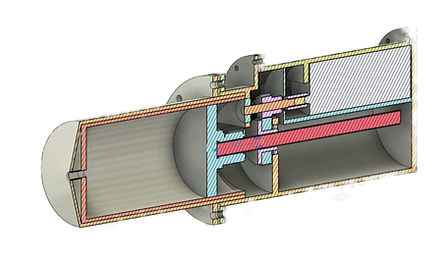

During the design process, commonly used valve mechanism-based ballast tanks and pressurized gas chambers in submarines were studied. However, due to the additional volume, complex structure, and sealing issues of these systems, a simpler, more reliable, and compact syringe-based piston-rod mechanism was chosen instead.

The system is integrated into a special watertight shell located outside the vehicle's body and consists of a step motor, a threaded rod, a piston, and a syringe chamber. The motor-driven threaded rod moves the piston linearly. This movement creates a pressure difference inside the syringe, allowing water to be drawn in from the external environment or expelled. Thus, the system enables the vehicle to sink or rise using only this mechanical movement, without any propulsion.

The key components of the system are:

-

A 500 mL syringe chamber with a diameter of 7 cm and a length of 19 cm,

-

A 15 cm long threaded rod,

-

Watertight seals at the front and rear shells,

-

Special parts to fix the rod and motor,

-

Pass-through openings suitable for water drainage.

The external shell is designed in a cylindrical shape, with a length of 35 cm and a diameter of 9 cm. The rear cover's open-close structure allows for easy maintenance and assembly. IP68 certified waterproof connectors are used for cable transitions.

Two symmetrical versions of this system are installed on the vehicle, ensuring that the sinking and floating processes are carried out in a balanced manner. Cylinders mounted via support rods to the body are positioned to rotate 70 degrees and are located under the wings.

This system works by expelling the water it takes from the external environment directly back out. No chemicals or oily liquids are used, making the system completely environmentally friendly and eliminating the risk of leaks.

Computational Fluid Dynamics (CFD) Analysis of the Vehicle

This study addresses the numerical solution of the external flow problem for an autonomous underwater vehicle. CFD analyses were conducted to examine the hydrodynamic behavior of the vehicle at low speeds and to assess its design performance. The analyses provide critical data to optimize the vehicle's design by examining the flow patterns, velocity distributions, and turbulence effects around the vehicle. Simulations were carried out at speeds of 0.5 m/s and 1.88 m/s to evaluate the vehicle's performance at different speeds.

The mesh used in the analyses consists of a polyhedral structure with approximately 4.6 million nodes, 13.2 million surfaces, and 4.3 million elements. This structure was chosen to improve solution accuracy and computational efficiency. A fine mesh structure was applied to the vehicle’s surface and surrounding areas to more precisely resolve high turbulence regions, thereby modeling the boundary layer behavior more accurately.

The simulations were carried out in steady-state regime, and the turbulence model used was the RANS-based SST k-ω (Shear Stress Transport k-omega) model. This model is commonly used in underwater applications due to its ability to better predict boundary layer separations. The pressure-based approach was used for the solution, and the outlet boundary condition was set as static pressure (outflow). The convergence criterion of 10⁻⁶ was applied in the numerical solution.

The analyses were performed at two different speeds. For the first speed of 0.5 m/s, the results were obtained without including the water pressure at a depth of 20 meters and were manually corrected afterward. For the second speed of 1.88 m/s, the solution was obtained directly without considering the water pressure. In both speeds, the flow fields around the vehicle were examined, and the effects of turbulence were observed.

Mesh Generated for the Analysis

Velocity Animation

at 0.5 m/s Condition

Pressure Animation

at 0.5 m/s Condition

Velocity Animation

at 1.88 m/s Condition

Pressure Animation

at 1.88 m/s Condition

Electrical Architecture of Our Vehicle

The electronic design of the vehicle focused on modularity, ease of production, and safety factors. Power consumption calculations were made using the data obtained from the analyses conducted by the analysis team, and the power infrastructure was designed accordingly. During the design process, the ease of access to purchased components was an important factor. The goal was to keep the design as simple and safe as possible, which makes maintenance and repair of the vehicle easier and minimizes the potential risk of harm to human health.

Power Infrastructure

The energy source of our autonomous underwater vehicle consists of three lithium-polymer batteries: two 4S 10000 mAh batteries and one 2S 7400 mAh battery. The different voltage levels required by the electronic components are provided through various voltage regulators.

Subsystems

The torpedo and dropper systems are controlled by individual servo motors. The ballast system is powered by high-torque motors with reducers. Pneumatic tubes, when the gripper is used, open sideways with servo motors located on both sides, enabling the embedded gripper system in the vehicle to open.

The gripper system is controlled by two servo motors, ensuring precise control. Feedback loops created with additional sensors monitor whether the gripper successfully holds an object.

Since modularity is sought in all subsystems, the electronic system is also designed in a modular way. This allows all subsystems to be easily removed and installed, enabling isolated testing of each subsystem.

Safety System

The temperature, water leakage, and flow sensors are integrated into a kill-switch circuit that prevents damage to both the vehicle and its surroundings. In addition to the flight controllers, a safety controller will be added to monitor the vehicle's safety. In situations like leaks, which pose a significant threat to the vehicle, communication is established with the main controllers to prevent potential crises.

In case of emergency, the kill-switch circuit is triggered by the emergency button, instantly cutting off power to all motors through high-current-resistant relays. This ensures that the vehicle does not cause harm to itself or its surroundings in emergency situations.

Software Architecture of Our Vehicle

Underwater Control Card

Pixhawk, Radiolink model was used as autopilot system and supported by an external IMU (MPU9250). This setup is optimized for stable movement and accurate position determination under water. IMU data is processed by PID-supported control algorithms running on Raspberry Pi 4B, so the signals sent to the thrusters can be adjusted in real time. Thanks to this structure, our vehicle can perform stable and precise maneuvers in six axes (6DOF).

Simulation

A system architecture based on ROS2 (Humble) was established and integrated with the Gazebo Harmonic simulation environment. This environment was customized with the “bluerov2_gz” package, and physical conditions were simulated in six axes. The real flight control software is tested with the ArduSub SITL integration, and the simulation data is visualized with Rviz2. In addition, the mission algorithms and positioning systems are tested and validated in advance in this environment.

Software Architecture

The software infrastructure of our autonomous vehicle has been developed with a focus on high reliability and performance using Python and C++ programming languages. The system executes its tasks through two main processor boards:

-

NVIDIA Jetson Orin NX: Handles image processing and AI-based tasks.

-

Raspberry Pi 4B: Responsible for sensor data, motor control, and other general control operations.

A high-speed and stable data transfer connection has been established between these two processor boards via Ethernet, and communication is facilitated through the ROS2 (Robot Operating System 2) framework. Real-time data sharing between the two processors is achieved via ROS2 topics, ensuring seamless synchronization between the systems.

On the Jetson Orin NX, environmental sensing is performed using a YOLOv11-based object detection algorithm integrated with the OpenCV library, allowing dynamic task planning.

Communication with the Pixhawk flight control board installed on the vehicle is conducted via the pymavlink protocol; motion commands, task initiation, and sensor data retrieval are managed through this system.

The overall system integration has been completed using the BlueOS platform, and version management, distribution, and secure operation across multiple development environments are ensured using the Git version control system and Docker container technology.

All software components developed have been made available to the community through our official repository on GitHub as open-source.

To enhance the vehicle's environmental awareness and optimize task performance, both mono and stereo cameras have been integrated into the system. These cameras support the following tasks:

-

Real-time object recognition

-

Image processing

-

Simultaneous localization and mapping (SLAM)

Additionally, special lighting hardware has been integrated into the vehicle to improve image quality in challenging environmental conditions and enhance the performance of the object recognition algorithm. This ensures task effectiveness even in low-light or blurry environments.

For operators interacting with the system, a user-friendly and functional interface has been designed. This desktop application, developed using the PyQt5 library and Qt Designer tools, allows for:

-

Vehicle motor control

-

Camera image monitoring

-

Access to compass and sensor data

-

Basic motion and system tests

The interface has been configured to support remote access. Through the SSH protocol, the vehicle and surface computer can communicate securely on the same Wi-Fi network, enabling the operator to remotely control the vehicle.

Algorithm Design

-

Dive-Ascent System Algorithm: The syringe system is integrated with the pressure sensor and managed by a PID controlled depth fixing algorithm.

-

Motion Control: By combining sensor data with the Kalman filter, PID-supported motor signals are created.

-

Navigation: OpenVINS based visual-inertial odometry (VIO) system is used. This system is powered by a specially trained deep learning-based feature detector and provides 30% accuracy increase in underwater conditions.

-

Task Algorithms:

-

Lost Treasure Hunt: Route planning with D* Lite algorithm.

-

Cable Tracking and Anomaly Detection: A hybrid system was created with the combination of YOLOv11 and color filtering.

-